Transloading vs. Direct Shipping: Which Saves You?

In the ever-evolving world of logistics, businesses constantly seek the most efficient and cost-effective methods to move goods. Two prominent strategies – transloading and direct shipping – offer distinct advantages and disadvantages, and the optimal choice hinges on a company’s specific needs.

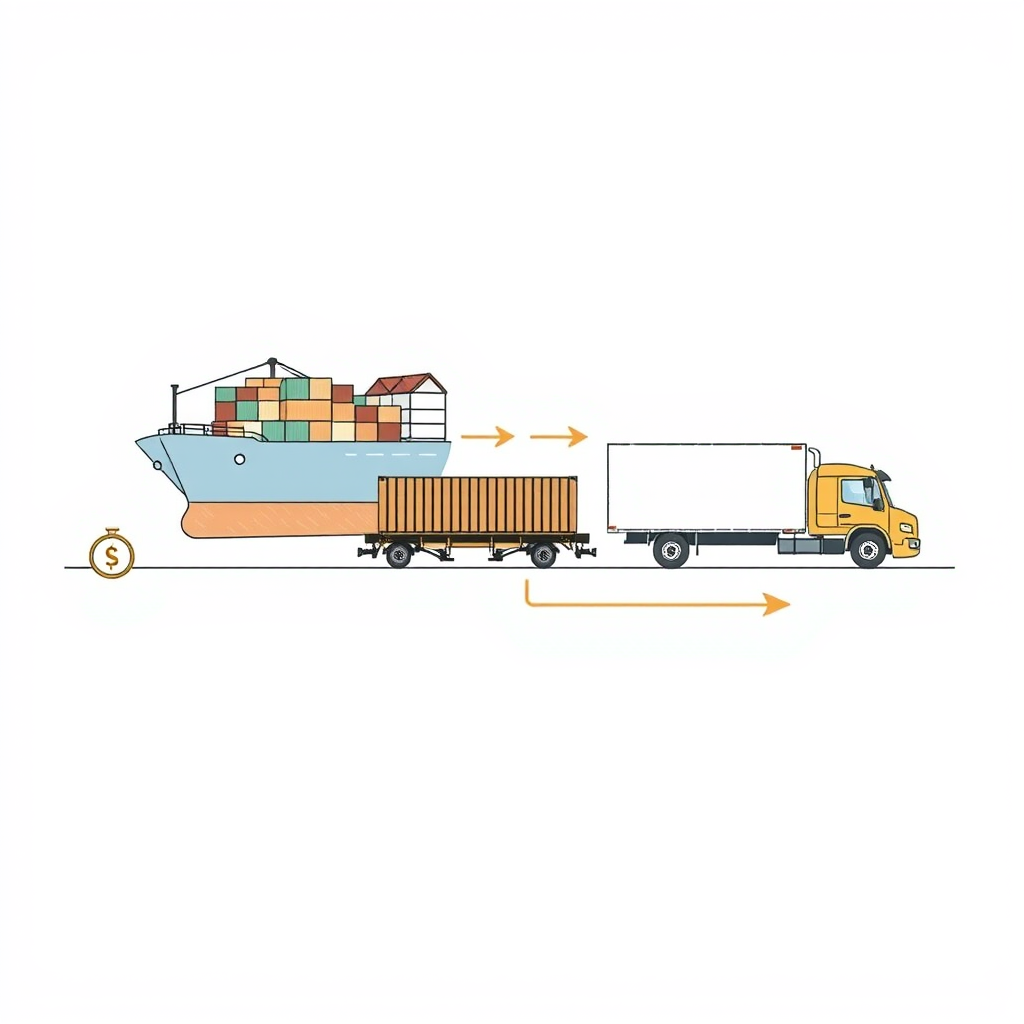

Transloading involves transferring cargo from one mode of transport to another – for example, from a ship to a truck or train. This is particularly useful for international shipments where reaching the final destination requires multiple transport methods. The benefits include greater flexibility through multimodal logistics, potential cost savings by leveraging the most economical freight options, and access to efficient route networks. However, transloading introduces complexities – coordinating multiple carriers, increased risk of delays and product damage, and potential extra charges for handling and storage.

Direct shipping, conversely, involves transporting goods directly from origin to destination without intermediate stops or mode changes. This method is often favored for domestic shipments, typically relying on a single truck delivery. Direct shipping boasts reduced transit times, lower risk of damage due to minimal handling, simplified tracking, and enhanced customer satisfaction. Its drawbacks include limited flexibility, potentially higher costs for long distances, and challenges with scalability for large volumes or international operations.

The key differentiator boils down to several factors. Direct shipping generally wins on speed, but strategically located transloading hubs can close the gap. Transloading often offers cost advantages by utilizing economical freight segments, while direct shipping can become expensive over long distances. Transloading provides greater flexibility, especially for international or multi-state deliveries, while direct shipping minimizes handling risks. Finally, transloading supports scalable, global operations, whereas direct shipping is best suited for domestic or regional needs.

The ideal solution isn’t always clear-cut. Businesses operating internationally and handling containerized shipments, or those frequently using intermodal transport, often benefit from transloading. Conversely, companies prioritizing speed for domestic shipments, minimizing product handling, or dealing with perishable or high-value goods typically favor direct shipping.

Increasingly, a hybrid approach is gaining traction. Companies are combining both strategies – for example, moving goods from ships to trucks for final delivery to retail locations – to balance speed, cost, and flexibility. Emerging technologies like real-time tracking, AI-powered routing, and data analytics are further enhancing the attractiveness of both approaches.

Environmental considerations are also playing a growing role. Transloading can reduce emissions by utilizing more energy-efficient modes like rail, while direct shipping minimizes handling waste. However, direct shipping can be less fuel-efficient over long distances.

Ultimately, the choice between transloading and direct shipping isn’t one-size-fits-all. A thorough assessment of operational needs, shipment profiles, and customer expectations is crucial. A hybrid model often provides the best of both worlds. Logistics is a dynamic field, and adapting a supply chain strategy to unique needs is essential for optimal performance and customer satisfaction. It’s a smart move for businesses to regularly re-evaluate their approach, considering not just cost and speed, but also sustainability and technological advancements.